History

The foundation of the Hall-Mark company dates back to 1767 when the Halls, a wealthy ship-owning family from Hull, first became involved in rope making in Barton. The town already had a workforce of skilled dressers, spinners and rope makers. In 1800, the Hall family bought the land to the east of Barton Haven to establish a permanent rope works in Barton. The whaling and fishing fleets of Hull and the shipbuilding yards provided a rich and diverse market for Hall’s products, including ropes, sailcloth, twine and tarpaulins. Imported hemps, flax and other fibres from around the world rapidly replaced local materials. By 1851, the factory was powered by steam and lit by gas.

Origins

Like most rural communities, Barton people grew flax to provide for their own domestic needs.

The town’s ancient links to the River Humber and the sea beyond helped boost the local demand for rope and sailcloth, as did the large number of windmills that existed in this region. The production of flax and hemp is mentioned in the Barton Town Book of 1676, which clearly places its role at the heart of the parish’s economy. However, rope making in Barton did not (or rather could not) engage with wider markets. This stemmed mainly from the small-scale nature of the process. Inventories left by ‘Ropers’ during the seventeenth century show that few, if any, possessed any sort of machinery to help them increase production. Indeed, illustrations dated 1802 show men spinning rope by hand, making it anywhere they could ‘walk’ the length required. Subsequently the early history of rope making in Barton has left historians and archaeologists with no firm evidence.

We do know, however, that Halls’ first permanent and substantial rope making building was built at Barton some time between 1800 and 1806. This, for many, represents the beginning of industrial rope making in the town. But, the story of the Hall’s Ropery begins much earlier, in the eighteenth century, in the nearby port of Hull. As the eighteenth century progressed, Hull was developing rapidly as a port of great significance; export trade had doubled between 1750 and 1780. The merchants and traders of Hull were increasingly wealthy, and the Hall family almost certainly profited from the development of trade from the port.

Traditionally, the date given for the foundation of Hall’s Ropery is 1767. It is probable that this was the initial move by William Hall into the business of rope making, rather than any concerted effort to build a rope making ‘factory’ at Barton. The Hall family were successful merchants and ship owners, securing great wealth from trading to Baltic and European ports. It is likely that the Hall family’s Baltic trade links complemented their new rope making interests, as the importation of Russian hemp became common for rope making during the eighteenth century.8 Before the nineteenth century, rope making in Barton represented only a small (but increasingly important) part of the Hall family’s interests.

1800 – 1850 Foundations

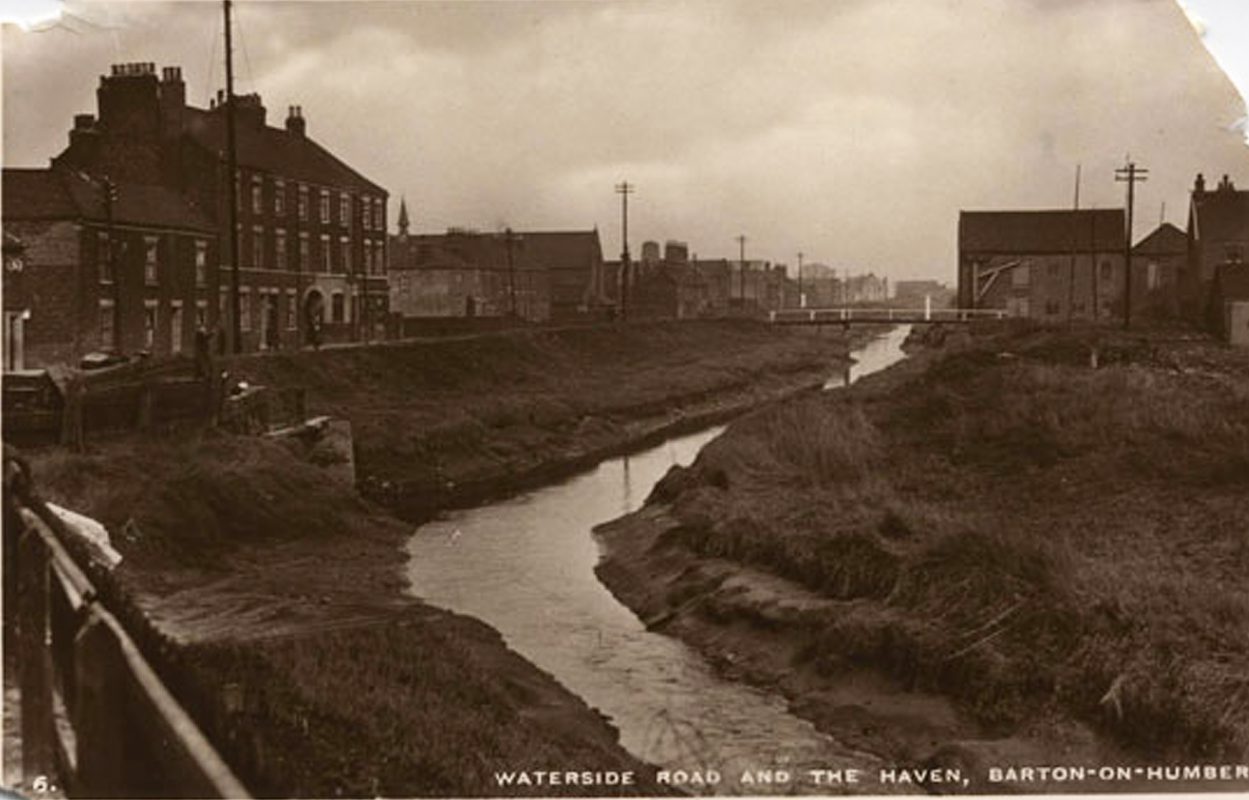

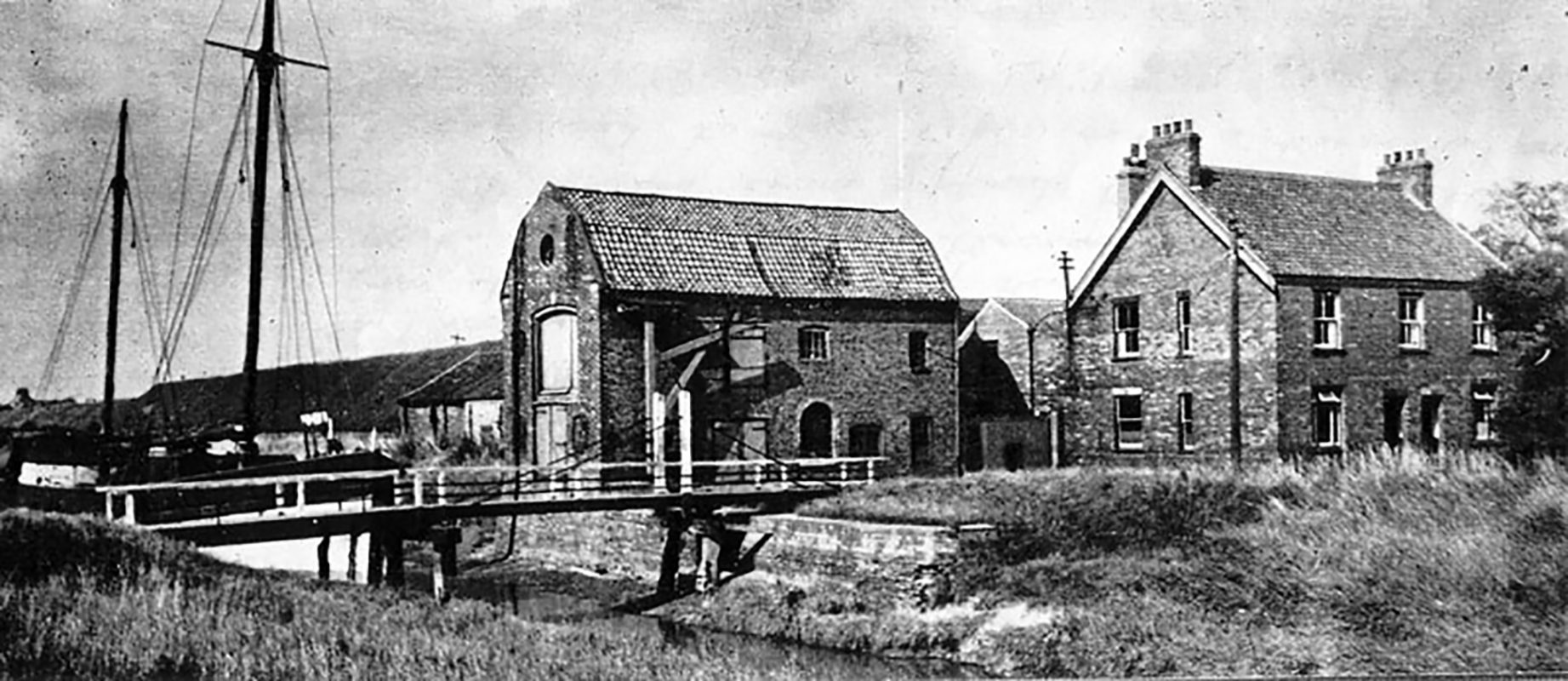

The foundation of a ‘modern’ rope works, with permanent buildings and the characteristic ‘walk’ occurred sometime between 1800 and 1803 when Thomas Hall and his son William purchased land on the east side of Barton’s Haven. Almost immediately, and certainly by 1802, the business and land was transferred to John Hall, Thomas’s eldest son and William’s brother. Born in 1775, John was still a young man, but one with a wealth of nautical and trading experience. Having become the successful master of one of the family’s ships in 1796 he was willing to explore markets not usually exploited by Hull’s merchants, such as those in the West Indies. However, his main trading links focused on the Baltic ports, and along with many other members of Hull’s merchant community, he was quick to exploit the growing whaling industry. In 1804, one of John’s ships brought home a record whaling catch, which was never surpassed in the forty or so years the industry remained active in Hull.

It was John Hall who began the development of rope making in earnest, and in 1808 he filed a patent for an improvement in the process. This was during a period in which technological innovation in rope making was developing quickly, and technical pioneers were becoming very wealthy men. Throughout his lifetime John invested capital in the rope works, and aligned his shipping interests to serve it. Indeed, in 1852 it was noted in the Stamford Mercury (in one of the few instances when the rope works is mentioned) that John Hall had undertaken to deepen the Haven so as to let boats unload easier at his works. As the nineteenth century progressed, the rope works expanded steadily. Gas lighting was introduced, and sometime before 1851, steam power was first used at the site. This development did not go unnoticed by the first generation of Barton’s historians, such as Charles Henry Ball and William Hesleden, who mentioned the rope works in their accounts of the town written during the 1850s. In no uncertain terms they ascribed the rope works the role of both major employer, technical innovator, and importantly, a main factor in the development of Barton as an industrial town.

1850 – 1900 Production

John Hall died in Baker Street, Hull in 1863. His son, John Edward, was the first member of the Hall family to run the factory from Barton itself. It was John Edward Hall who remained in charge until the company was reformed in 1890. John Edward Hall ensured Hall’s Ropery expanded greatly during his tenure, especially in regard to the development of steam power for making ropes. It is known that in 1864 John Edward financed the building of a Mission Church, built as part of the rope works buildings, and there are several documents which detail charitable donations to Hull Trinity House and various other charities.

Few setbacks occurred in this period of prosperity, despite a fatality in 1855 and a flood in 1868 being noted in contemporary sources. However, the later nineteenth century presented the company with problems which lead to its near collapse in 1890. The ending of the age of sail saw demand for traditional rope rigging fall significantly, and the introduction of steel cable did nothing to help this trend. For a company that still relied so heavily on the shipping of Hull and Grimsby, the effects on the business were grave, and when combined with a generally poor national economic performance in the later 1880s, were nearly catastrophic. The advent of steam fishing left many smaller fishing outfits completely redundant, and the company subsequently suffered heavily from bad debts during this period.

So in 1890, Hall’s Barton Ropery Co. Ltd. was created as a private limited company to raise enough capital to survive the troubles of the period, and was financed substantially by the Sissons family. Hall’s Barton Ropery made it a priority to engage in wire rope manufacture, and began this in 1891. No wire rope was actually produced on the ‘old’ Barton site, instead the company purchased Overton Brother’s wire rope works in Beverley. The capital expenditure of £15,000 used to save the company was a substantial amount, but it seems this investment was not matched by a change in focus by the company, as by 1900, 50% of the company had to be sold to the Wilson Shipping Line of Hull. This was attributed mainly to a continuing reluctance by the company to export their products. It is probable that the company contracted, as it is recorded that many of the company’s ships were sold in 1891, leaving perhaps as few as two in its ownership throughout the 1890s. (In comparison, sixty years earlier, John Hall had built and registered four ships for use by the rope works). The company then moved to offices in De La Pole House in Hull, a fine medieval town house. This was a proud asset but sadly became the last resting place of the company’s archives which were destroyed by bombing during the Second World War.

1900 – 1950 War years

In 1901 Arthur Hendy joined the company as cashier. He later became Managing Director, and his family name was associated with the works for the best part of the following century.

Although no dividends were paid in the first few years of the new company’s existence, recovery did eventually take place. The company probably benefited from the opening of Immingham docks in 1913, then the largest deep water dock in the United Kingdom, and a huge boost to the shipping economy of the Humber region. The relatively new ports of Grimsby and Goole also continued to develop, and after surviving the difficulties of the great changes in the fishing industry which nearly closed the company, the ropery profited from the ‘new’ industrial scale fishing based there in the early twentieth century.

During the first decades of the twentieth century, the company began to profit from the snowballing military build-up. As early as 1908 the company produced ropes designed to tow Dreadnought battleships. These were of up to forty inches in circumference, then the largest the company had produced. During the Great War the company was a large producer of all kinds of rope for military use, and the Admiralty orders represented the watershed for the company’s wire rope division. It became a prime national producer of steel guy-wires for aeroplane wings, and anti-submarine nets; both uses for steel wire essentially resulting from the needs of war. Subsequently, in 1918 the company was in a strong position relative to other, smaller, rope manufacturers. In 1920 Thomas Hall Sissons died and was replaced as Chairman by Arthur Barton Hall, (as his name suggests, he was indeed the first member of the Hall family to be born in Barton!). He was the son of John Edward Hall. In 1921 much of the ropewalk was damaged by an unusually high tide, and the majority of the present building dates from the rebuilding that took place around 1922. As part of this rebuilding openings were included in the walls of the ropewalk to enable any future floodwater to drain freely. These openings can be seen on the outside of the building today.

The wire rope division remained profitable throughout the troubled economic conditions of the early 1920s, but the natural-fibre works at Barton suffered to a much greater extent. The decline of the coal industry culminating in the general strike of 1926 had an immediate effect on the demand for ropes. As the full extent of the Great Depression became clear, it seems that the wire rope division was the company’s salvation, offsetting the losses of around £10,000 that the Barton site suffered during the early 1930s. Indeed, by 1939 the wire rope works were producing four times as much material as they had in 1936. A major contributory factor to the company’s recovery was the re-armament immediately preceding the Second World War. Following the declaration of war, production was controlled directly by the Admiralty and once again the company played a significant role in the war effort.

In the immediate post-war period the company was in a relatively strong position, but heavy taxation precluded any possibility of making much profit.

1950 – 1989 Specialist ropes

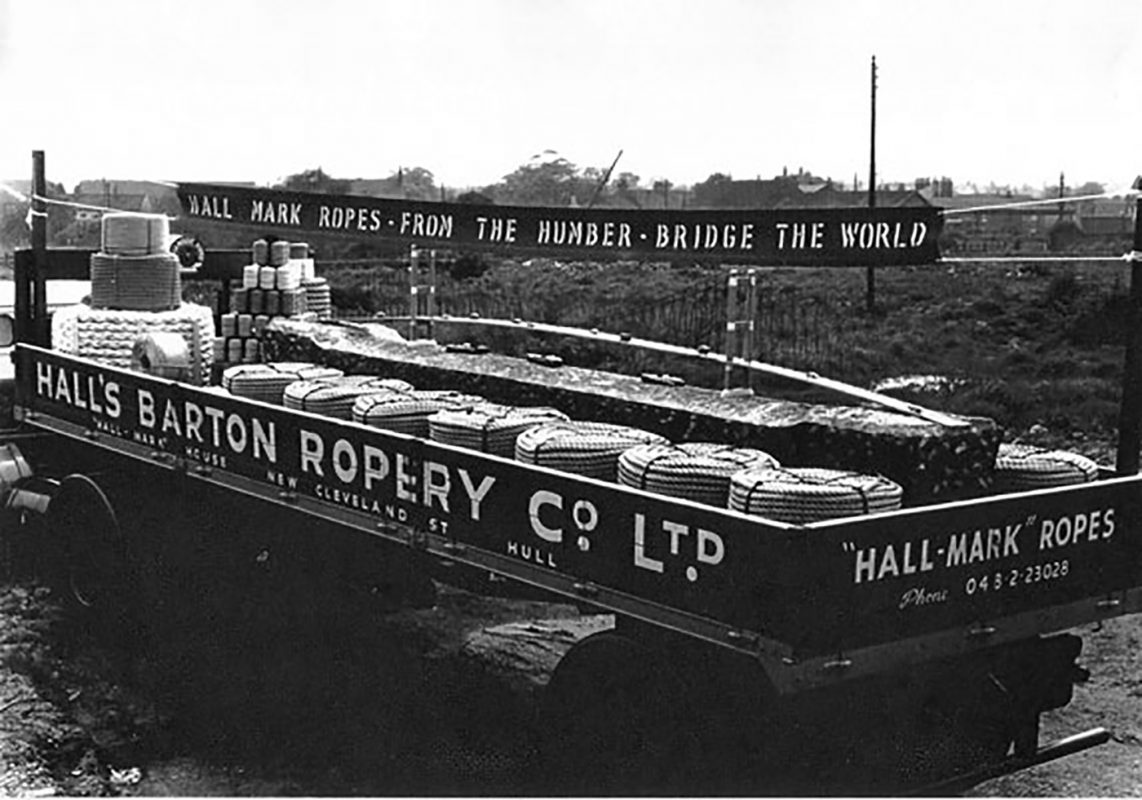

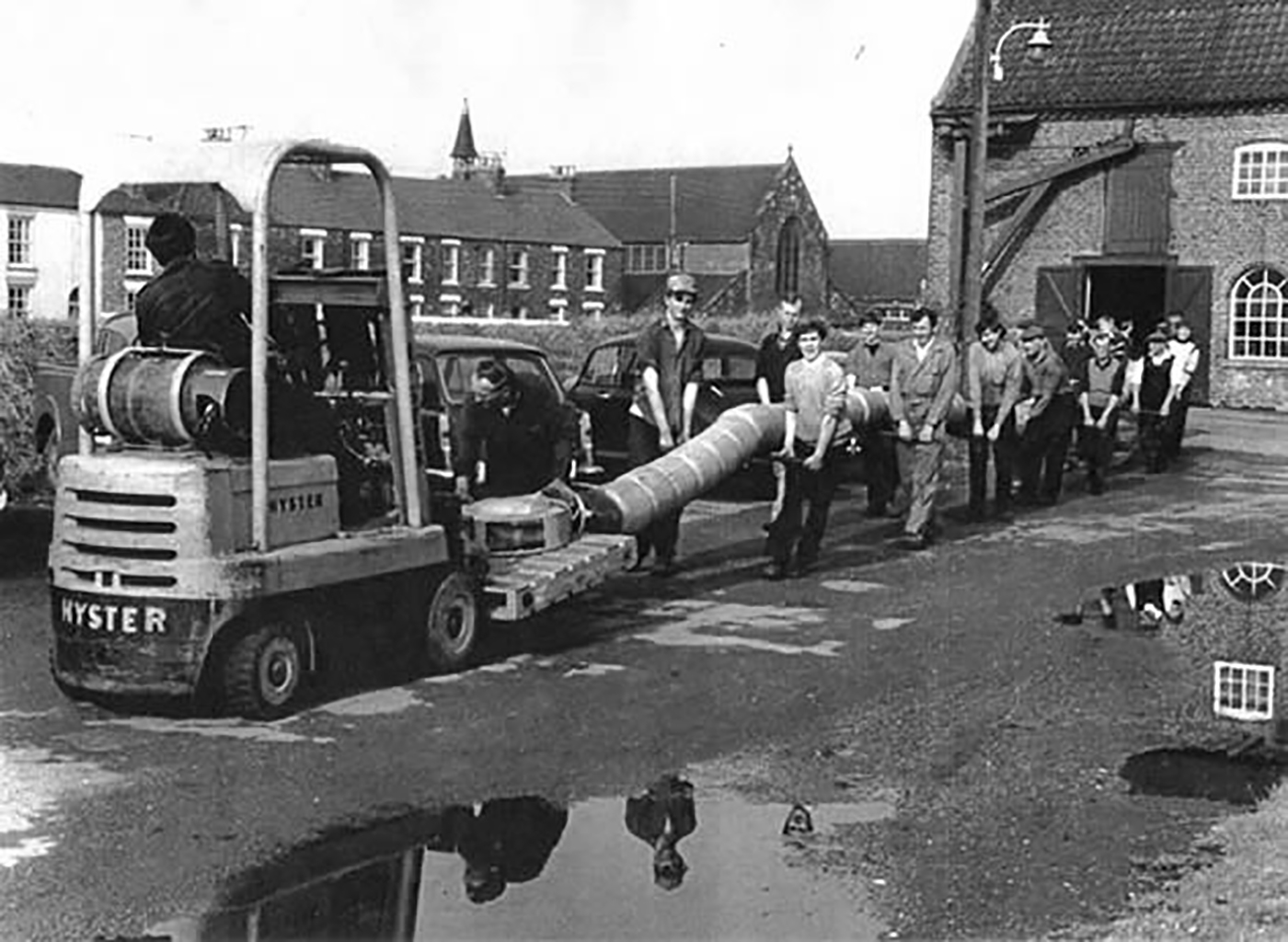

Roland Dagwell, who had joined the company in 1938 as Export Manager, returned from wartime service and continued to develop the company’s overseas business. Dagwell must have realised the importance of foreign markets in a time when ‘export or die’ was the order of the day. When he became Managing Director in 1953, after the death of Arthur Hendy, he continued the development of foreign trade, especially creating links with the burgeoning heavy-industries in South America and the Middle East. This coincided with the opening of new offices in Hull to replace those lost during the Second World War. Throughout the 1950s the business was stable, and foreign markets grew in importance; rope was in demand for all sorts of uses including oil drilling, mining, haulage and shipping. The company was compelled to invest in modern machinery and re-organised its storage systems to improve efficiency, although by far the most notable development was the adoption of synthetic rope making.

Synthetic fibres were to revolutionise rope making, being stronger, lighter, waterproof and cheaper to produce than natural ropes. Machinery to exploit synthetic rope production was built on the site of some older, by then redundant, processes at Barton, such as the production of ‘tow’ rope (poor quality rope re-manufactured from scraps). The development of synthetic fibres, beginning with polyester, moved with great pace and by 1960 synthetic fibres of modern standards were available. Hall’s found the production of synthetic rope profitable; evidence shows that much of the synthetic rope was used in ‘everyday’ applications where it replaced sisal and manila rope. The company remained in the business of the production of natural fibre ropes, and it appears they aligned this aspect of the business to the fulfilling of specialist orders where the proven qualities of manila or sisal rope were sought over the lower price of synthetic ropes. Indeed, as many other rope manufacturers contracted and closed, Hall’s Barton Ropery remained one of the few rope manufacturers in the country that could produce ropes of unusual characteristics; in length, lay or quality. Certainly, large companies such as British Ropes tended to abandon such specialist rope in favour of the production of synthetic alternatives. Alas, it could be argued that Hall’s could not compete with such large industrial combines and the decision to remain a ‘specialist’ rope maker was probably one made with little choice, eager to remain independent in a period when many smaller rope works were struggling. Those with fond memories of the company often recall the ‘special’ ropes the company made, and it has often been said that the ropes used on the first successful ascent of Everest were produced in Barton. Unfortunately, no documentary evidence remains of this achievement. There were many orders from such unusual customers as the United States Navy who provided very detailed specifications and expectations of quality.

The company continued to be successful throughout the 1960s, Roland Dagwell becoming Chairman in 1962. The company’s success fitted well with the general success of all industry in the Humber region, notably in the emergent chemical, paint and oil industries. Rope making as an industry remained an important part of manufacturing in the area, accounting for 4.5% of the region’s production in 1967, the bulk of which must have derived from Hall’s Barton Ropery. In the home markets the company relied heavily on orders from repeat customers, and state owned industries such as the British Coal Board, British Steel Corporation, British Railways, and numerous other utility and shipping boards. Modernisation of the works and its machinery carried on, and gained pace when Tom Nicolson became Work’s Manager. Money was always a problem though, and during this period it was a constant struggle to keep the old ropewalk building weather proof. Eventually, and in line with national requirements regarding working conditions, the southern part of the walk, dating from the first decade of the nineteenth century, was rebuilt in metal and asbestos.

During the 1970s the area suffered greatly from economic recession. The attendant loss of many fisheries effectively brought to an end Hall’s centuries-long association with the British maritime industry. New avenues were explored and Hall’s Barton Ropery made a good name for itself in Icelandic and Canadian fishing markets. Business was hard and Hall’s found it increasingly difficult to maintain stock levels and therefore quick deliveries. Despite their struggle to remain independent, Hall’s could not prevent Bridport-Gundry purchasing the company in 1986. Before Bridport-Gundry’s long-term plans for Hall’s Barton Ropery were revealed, the company was sold once again, to Bridon Plc, (formerly called British Ropes). The decision to close the Barton site was made immediately and, in December 1989, the works produced its last rope. The buildings were stripped and machinery either broken up or sold to other manufacturers. Centuries of rope making in Barton had come to an end.

Opening Times

10am - 5pm Tuesday to Saturday

10am - 4pm Sunday

Entry to the museum is free.

Contact Details

Museum

Unravel the history of Barton

Visit our heritage shop and buy online

Written by popular local historians, the Ropewalk shop stocks a range of books, journals and historical records documenting the Ropewalk's and Barton upon Humber's rich history.